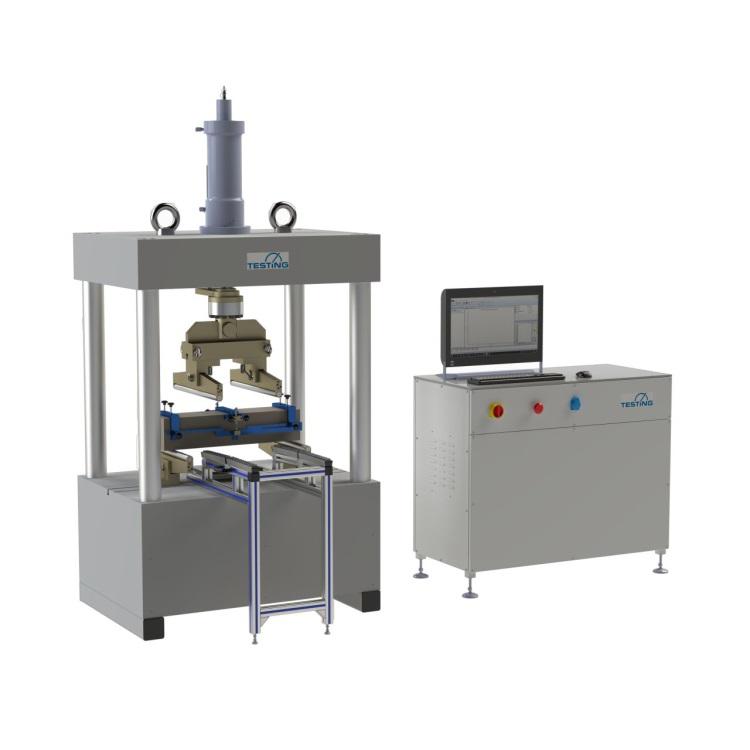

The bending testing machine is suitable for flexural strength tests of various concrete specimens, such as Concrete beams, curbs, concrete slabs, bricks etc. In the basic configuration, the frame is designed for force-controlled tests, whereby the force value is determined by a strain gauge force transducer (class 1). A displacement measuring system can optionally be installed. In the cylinder displacement- and deformation-controlled tests are possible. The solid steel frame is extremely stiff, and the columns are clamped without any play. A double-acting bending test cylinder with long piston stroke in servoslide quality (particularly low-friction) is mounted on the upper crosshead. An anti-rotation device prevents the piston rod from rotation of the piston rod with the upper bending knife. The upper bending knife can be easily converted from 3-point to 4-point testing. Other accessories such as curb dies, pressure plates etc. can be be adapted.

Standards: DIN EN 12390-5, 1339, 1340, ASTM C78, C293, C469, C496, C1019, C109/C109M

- Technical data

- Frame type: 4-column

Force display range: 0 - 100 kN

Force measuring range: 1 - 100 kN, class 1

Stroke: 220 mm

Distance between columns: Front 900 mm / Side 800 mm

Bending roll length: 620 mm

Bending roll diameter: Ø 40 mm (optionally other diameters and lengths)

Bending roll distance bottom: 80 - 840 mm - Control cabinet

- Control cabinet

Control cabinet SV-i20 with main switch inclusive under voltage release and emergency stop switch, as well as a protective contact socket in the front panel Connection CEE plug 16 A (3~400 V, 50 Hz) - Safety

- The testing machine is extensively equipped with an impact-resistant, transparent polycarbonate test chamber made of polycarbonate.

- Dimensions

- Test frame: (W x D x H) = 1170 x 1040 x 2280 mm

Weight: approx. 1000 kg

Control cabinet: (W x D x H) = 1200 x 570 x 1050 mm

Weight: approx. 280 kg

3 ~ 400 V / 50 Hz / 1,1 kW